Calculs d’engrenages

FERRY-CAPITAIN, c’est plus de 40 années d’excellence dans la conception, la fabrication et l’installation d’engrenages pour l’industrie lourde, pour des applications aussi variées telles que la minéralurgie, la cimenterie, la sidérurgie, les sables bitumineux, la chimie, l’alimentaire, etc…

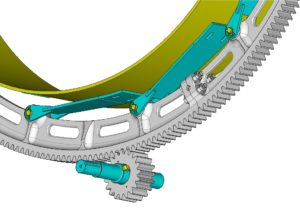

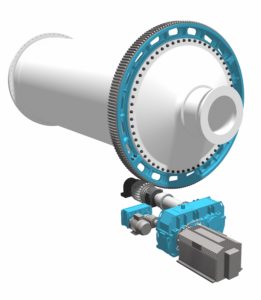

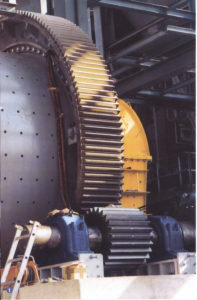

Nous concevons et réalisons des couronnes & des pignons de toutes dimensions jusqu’à 16 000 mm de diamètre extérieur. A ce jour, ce sont plus de 2 200 couronnes en acier et plus de 1100 couronnes en fonte GS et FerryNod®, nuance mise au point et brevetée par FERRY-CAPITAIN, qui sont sorties de nos usines.

AVANTAGES :

- Diagnostic

FERRY-CAPITAIN dispose d’une équipe de techniciens spécialisés pour procéder au diagnostic des installations à l’aide d’examens visuels, de prises d’empreintes, de mesures de températures sur les dents, d’analyses vibratoires.

FERRY-CAPITAIN assure l’interchangeabilité des pièces de rechange par une série de relevés dimensionnels sur les matériels d’origine.

- Calculs / Études

Ferry- Capitain et CMD avec leurs Services Ingénierie et leurs logiciels d’études par éléments finis, sont capables de dimensionner tous les engrenages d’après sa propre expérience et en suivant les normes en vigueur dans le monde (AGMA-DIN-ISO).

La totalité des prestations dont vous avez besoin peut être assurée par nos soins, en pleine collaboration avec par exemle CMD Gears, autre société du Groupe CIF, telles que : diagnostic des installations, relevés sur site, calcul de capacités de charge, définition et optimisation du design des produits et de leur matière, redimensionnement des boulons d’assemblage des parties de la couronne (en demi ou en quart), la fabrication du modèle à l’emballage, contrôle avec test d’engrènement sur machine si besoin, montage sur site et aide à la maintenance.

La durée de vie des roulements installés sur le (s) pignon (s) est aussi calculée et prise en compte.

Nous intervenons sur site avant la conception, grâce au département FC Services, dont les techniciens interviennent partout dans le monde.

FERRY-CAPITAIN réalise tous types d’engrenages à denture droite, hélicoïdale et à chevrons.

- Fabrication et mise en œuvre

Les équipements modernes et les techniques de moulage et de coulée permettent d’assurer une qualité optimum des matièresélaborées par nos fonderies. Les moyens d’usinage et de taillage assurent la réalisation des pièces dans les qualités requises.

Les techniciens du pôle FC Services assurent l’assistance et la maintenance clientèle en gèrant la supervision lors du montage et la mise en route des installations.

- Capacités

– Traitement thermique : 12 m x 6 m x 3,5 m ou Ø 9 m

– Tournage : 16 m

– Alésage : 16 m x 3,5 m

– Taillage : 16 m – module 60 mm