Gear Calculations

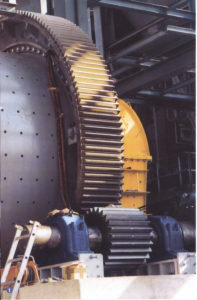

FERRY-CAPITAIN, is more than 40 years of design excellence heavy industry gears manufacturing and installation, for different applications mineral processing, cement, steel, oil sands, chemical, food, etc...

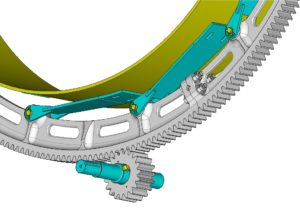

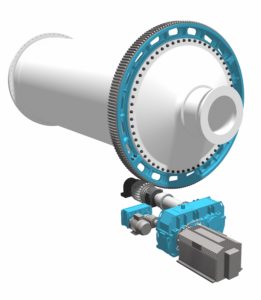

We design and manufacture ring gears & pinions of all sizes up to 16,000 mm outside diameter. To date, more than 2,200 steel rings and more than 1100 cast iron GS and FerryNod® rings, a grade developed and patented by FERRY-CAPITAIN, have been manufactured in our factories.

BENEFITS :

- Diagnostic

FERRY-CAPITAIN has a team of specialized technicians to diagnose the installations with the help of visual examinations, impressions, temperature measurements on the teeth, and vibratory analyses.

FERRY-CAPITAIN ensures the spares parts interchangeability doing a series of dimensional checking on the original equipment.

- Calculation / Studies

Ferry-Capitain and CMD, with their engineering departments and finite element design software, are able to design all the gears according to their own experience and following the standards in force in the world (AGMA-DIN-ISO).

All needed assistance is provided, in full collaboration with CMD Gears, part of Groupe CIF, such as: installations analysis, on-site dimensional checking, load capacity calculation, definition and optimization of product design and materials, ring-gear parts bolts resizing (in half or quarter), manufacturing from model to packaging, control with test machine meshing if required, on-site assembly and maintenance assistance.

Bearing lifetime installed on the pinion(s) is also calculated and considered.

We work on site before design, thanks to the FC Services department, whose technicians work all over the world.

FERRY-CAPITAIN manufactures all types of spur, helical and chevron gears.

- Manufacturing and Implementation

Modern equipment, forming and casting methods ensure a high-quality of materials produced in our foundries. Machining and cutting tools guarantee quality requirements in realised parts.

FC Services technician division ensure maintenance and customer support by managing the supervision during the assembly and commissioning of the facilities.

- Capacity

- Heat treatment: 12 m x 6 m x 3.5 m or Ø 9 m

– Turning : 16 m

- Bore: 16 m x 3.5 m

- Size: 16 m - 60 mm module