Aerospace

Ferry-Capitain is involved in the production of metallic tools for aerospace. Our R&D improvements works on design, material improvement to provide the best added value to our customers.

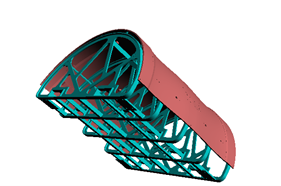

Lay-up tools

Supply of monobloc lay-up tools in Invar. The use of Invar offers several advantages.

- Low Coefficient of Thermal Expansion (CTE)

- Long life time compare to composite mold

- Adapted for high rate production

In addition, the foundry process allows near net shape and complex shape WITHOUT welding.

FC Frame

Our R&D engineers developed a special one part frame offering a competitive advantage compared to fabricated.

- Up to 50% lighter than fabricated

- Stable during curing cycle

- More energy efficiency in autoclave

RTM Molds

We are able to provide big Invar block up to 14m.

FerrynoxN29K: The special Invar for your thermoplastic applications

We developed a special Invar (patented) to match with the curing temperature of thermoplastic (720 °F/380 °C). The CTE remain stable to avoid spring-back effect.

Lay-up tools in FerrynoxN29K

Heat Resistant steel: Super Plastic Forming (SPF)& Hot Forming (HF) Dies

We supply dies made from our Ferrynox grades; high nickel alloys.

With extensive expertise, we can supply large tooling up to 17 tons. Our R&D department improves design and materials with the goal of extending the life time of the dies in service.

Design and materials according to your needs

Ferry-Capitain is able to provide solutions according to customer specifications.

Our approach to optimization comes from special alloy development and/or design approach.

Below are some examples of solutions we offer to our customers:

- special grade with high hardness up to 340 HB

- material with high conductivity (FerrynoxN95)

- high silicon cast iron (high elongation cast iron)

For more information, contact fc.aerospace@ferrycapitain.fr