Foundry

One of the specificities of FERRY-CAPITAIN is to be both a cast iron and steel foundry, with its own pattern making workshop.

Moulding

Our 900 m² workshop is equipped with many conventional machines as well as a 3-axis CNC..

Our team is composed of a dozen modelers working from plans or 3D models.

The staff is able to:

- To repair and to bring to compliance all wooden or polystyrene models in the factory or on the casting site.

- To ensure all model controls manufactured at FERRY-CAPITAIN as well as all models from subcontracting.

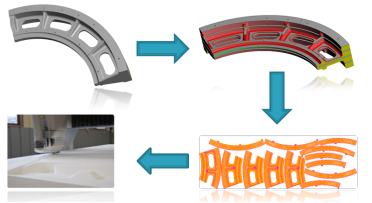

- To realise all dimensions polystyrene models with CNC

StratoCinception (StratoEngineering) completes the conventional equipment

Moulding and Coring

With the help of a model made in the modeling workshop, the casting workshop makes furanic sand impressions into which the metal will be cast.

FERRY-CAPITAIN has 2 casting sites: cast iron and steel casting.

These sites are equipped with large capacity mixers (60 T / hour) for the used of frame moulds (6 m²) or pit moulds (11 m * 8 m * 3 m).

Material grades:

- Cast Iron - Ductile, Grey, Alloyed (Cr, Ni-Hard, Ni-resist)

- Steel - Carbon, Stainless, Duplex, Alloy

Melting capacities:

- Cast Iron: 62 T (all furnaces combined), 340 T weekly

- Steel up to 100 per week

Melting means:

Electric furnaces and induction furnaces:

- 1 furnace of 1.5 Tons

- 1 furnace of 5 Tons

- 1 furnace of 10 Tons

- 1 furnace of 12 Tons

- 1 furnace of 16 Tons

- 2 furnaces of 8 Tons

- 1 AOD converter of 16 tons